Everything you ever needed to know about whisky cask storage

All over the world, whisky must be stored in casks for a certain number of years before it can be called whisky (or bourbon, or whiskey depending on where you are).

Experts suggest 70-80% of a whisky’s flavour is imparted through reactions in the cask. Even a whisky’s colour is created by the cask; the spirit that comes out of a still is clear (like gin or vodka). In most countries whisky only ‘needs’ to be legally matured for 2-3 years, but most single malt Scotch whisky is bottled when it is older, with spirit as old as 78 available (if you have deep enough pockets).

But whether it is for 2, 3, 12, 30 years or longer, where is all this maturing whisky stored?

All over the world maturing whisky casks are stored in bonded warehouses. The size shape and nature of these warehouses vary depending on in which country the whisky/whiskey/bourbon is maturing and within the country when that warehouse was created.

What is a bonded warehouse?

A bonded warehouse is one in which the goods that are stored inside have had their duty payments suspended. Duty is a type of tax levied on alcohol, but it is not payable until that cask is taken out of bond (i.e. bottled).

In the UK bonded warehouses are very highly regulated and HMRC keeps very close tabs on them due to the millions of pounds in duty owed on whisky. Even a very small warehouse with 2,000 casks will owe the UK government around £8,000,000. As such they are incredibly secure and are more like compounds than warehouses.

Bonded warehouse are also incredibly safe places to work. Consider the same 2,000 cask warehouse mentioned above. As well as the £2,000,000 in taxes the stock owes HMRC, it also houses around 400,000 litres of very flamable alcohol. Very tough Health & Safety rules are followed in bonded warehouses for two reasons:

- A warehouse fire could lead to a catastrophic loss of life (and stock)

- Any fire/theft/damage would have a huge eccenomic impact to the owners of the stock and also (and more importantly?) the government whom the taxes are owed

Given the very tough regulation of Scotish bonded warehouses, accidents, thefts and fires are almost unheard of.

This is in stark contrast to the USA where rack houses used to mature bourbon make headlines for fires and collapse. Needless to say Scotland does not have the searing heat of an American summer, but even if they did the construction and maintaince of the warehouses would make such instances almost impossible.

The most common types of warehouse for maturing whisky are:

- Dunnage

- Racked

- Pallet

- Rackhouse

What is a dunnage warehouse?

A dunnage is the type of warehouse that was traditionally used to mature whisky in Scotland. They are still used by some distilleries today mature whisky. Because dunnage warehouses are part of traditional whisky making and maturation they are generally located in the distillery grounds, or nearby, and are relatively small.

A dunnage has a dirt floor, thick stone walls and deep tiled roof. Some of the later dunnage’s to be built do have brick walls but traditionally they are stone. They are usually low ceilinged, and the barrels are stored just two or three high.

The dirt floor means a dunnage is traditionally humid and the thick walls mean the temperatures and humidity are fairly constant within the dunnage over daily and yearly cycles. The high humidity has an important impact on whisky as it matures.

Humidity and the Angel’s Share

The humidity within a whisky warehouse has an important effect on the whisky as it matures. In high humidity environments the rate of evaporation is higher for alcohol versus water, whereas in a low humidity environment the reverse is true. That means in high humidity warehouses the alcoholic strength will drop over time; this is the case in Scotland. In low humidity environments the alcohol strength may actually rise as water is preferentially evaporated; this is more typical in hot dry environments like Kentucky.

The dirt floor and low ceiling of a dunnage means that machines cannot be used, so cask management must be done by hand. This high intensity management increases the overheads associated with these types of warehouse.

Because a dunnage is often on the distillery grounds these are the warehouses that most people are familiar with from distillery tours. They also have a somewhat romantic look to them and appeal to people’s ideals of traditional industries. This has given rise to the belief that dunnage storage is better for the whisky than other types of warehouse. While it is true that different storage conditions may have different effects on the maturing whisky, whether this is discernible to the average drinker is debated, as is whether the whisky it matures is eventually better.

What is a Racked Warehouse?

A racked warehouse is a modern style warehouse that is much larger than a dunnage and was designed to deal with the increased volume of whisky needed to meet modern national and international demand.

Racked warehouses are usually made from modern construction; often brick or concrete walls and a thinner lightweight roof. Racked warehouses have a similar average temperature compared to dunnage but a relatively lower humidity due to the concrete floors. There is more of a seasonal change in temperature in a racked warehouse compared to a dunnage, and within the warehouse there can be more variation from the top to the bottom of the racks.

The seasonal change in temperature causes slight variations in the volume of the whisky in the cask over a year (warmer liquid takes up more space than colder). It has been suggested that this expansion and contraction of the liquid speeds up the maturation process. Low humidity also causes casks to mature faster than high humidity, and impacts how the angel’s share impacts the alcoholic strength. Therefore, casks may mature quicker in a racked warehouse, and lose less alcoholic strength compared to a dunnage. Whether that is good or not is discussed in more detail below.

In a racked warehouse the barrels or casks are stored on their sides (in the traditional manner) in stacks 8-12 high. The size and layout of the warehouse means the casks can be moved by machines, which allows much more efficient cask management. This makes it easier for the warehouse to manage, and the end result is reduced costs to drinkers.

Racked warehouses can be found on the distillery grounds but are often in a central location. This is a point of consternation for some that we will discuss below.

What is a pallet warehouse?

A pallet warehouse is another type of modern warehouse. The construction and temperature controls are similar to that of a racked warehouse, but the casks are stacked upright (rather than on their side as is traditional) on pallets.

Stacking casks on their end has two significant impacts on maturation.

Firstly, it reduces the surface area for interactions between the cask and the whisky, and this slows down the maturation process.

Secondly, it reduces the rate of evaporation (the angle’s share) and reduced the acceleration of that evaporation over time. This is because when a cask is stood on its end the surface area exposed to the air in the cask is reduced, which reduces the rate of evaporation. In addition, when a cask is stored on its end the surface area exposed to the air does not increase significantly as the level in the cask drops as it would when a cask is stored on its side.

As a working example think about a pop bottle lying down in your fridge. When you first get it the you can see the small oval that is in contact with the air inside the bottle. If you drink a glass and put it back that surface gets bigger, and each time you take a glass it gets bigger again.

This is like the traditional way of storing casks on their side and the angel’s share accelerates over time because the surface area for evaporating increases as evaporation happens – a positive feedback loop.

Conversely if you pour a glass and then store the bottle upright the surface area in contact with the air does not change much as you consume each glass. (If you want to extend the analogy you will find your pop does not go flat so quickly if you store it upright as there is less surface area for the gas to escape). It is the same with casks; the angel’s share accelerates over time because the surface area for evaporating increases as evaporation happens – a positive feedback loop. For casks stood upright this acceleration is reduced because of the shape of the cask.

Whether this has a positive or negative effect is personal preference. Arguably slower maturation is preferred in whisky. But the angel’s share is a traditional part of maturation and development of flavour and helps create a balanced taste profile and palatable abv.

The big thing about pallet warehouses is that they can be completely automated. And the biggest impact that will have on the average drinker is through reduced bottle prices.

What is a rackhouse?

A rackhouse (we have also seen it termed rickhouse too) is the term used for the warehouses used to mature bourbon whiskey. These are very tall buildings often with a metal roof, that are split into several floors (traditionally 9) that each store 2-3 layers of casks.

The traditional construction of rackhouses means the internal temperature and humidity are much more influenced by the external conditions. Hot summers and cold winters cause the bourbon to expand and contract, increasing interaction with the cask and making it matures faster. The low humidity and high temperatures also mean that the alcoholic strength of bourbon tends to increase as it is matures because water is preferentially evaporated as the angle’s share.

A bourbon rackhouse tends to have significant variation in temperature and humidity within the warehouse. The middle of the rackhouse remains relatively constant compared to those on the edges of the warehouse and the top levels tend to be relatively warmer.

The significant differences in temperature and humidity between the different areas of the warehouse also cause variation between the casks as they mature. It used to be that around a third of the warehouse had to be left empty in order to allow cask rotation. This solution was inefficient and time consuming so now master blenders combine casks from different areas of the warehouse in order to create a standard finish for their signature batches.

If a single cask bottling is required, this tends to come from the centre of the warehouse where the temperature is most constant and the humidity highest.

Where is Japanese Whisky matured?

The process of making whisky was introduced to Japan from Scotland. The Yamazaki distillery was the first Japanese distillery and was created with the help of Masetsaka Taketsuru who trained in Scotland. He went on to found Japan’s second distillery, Yoichi.

The result is a strong adaption of Scottish traditions in Japanese whisky including their use of and style of warehouses to mature whisky.

The real difference is the climate. Scotland has a temperate maritime climate with cool wet winters and cool wet summers. Japan has a tropical maritime climate with hot humid summers and cold snowy winters.

This produces very different conditions within Japanese warehouses compared to Scottish ones so that even though the techniques and principles are the same, the end result is very distinctive.

Does warehouse location impact taste?

The big question around warehouses is what impact do they have on taste? We have discussed the basics of the difference between the principle types of warehouse and have touched upon how their construction can shape the whisky stored in them through humidity and temperature regulation.

Of course, the warehouse’s location is going to have the biggest impact on the humidity and temperature experienced by the maturing whisky. Japanese whisky is the perfect example of this; even though they have adopted similar techniques to those used in Scotland, the whisky they produce is inimitable.

The evolution of whisky storage

Traditionally distilleries had small dunnage warehouses on their grounds, but as production grew and whisky became an international product the space needed to store the millions of litres of alcohol produced each year quickly outgrew the storage available on site.

Did you know?

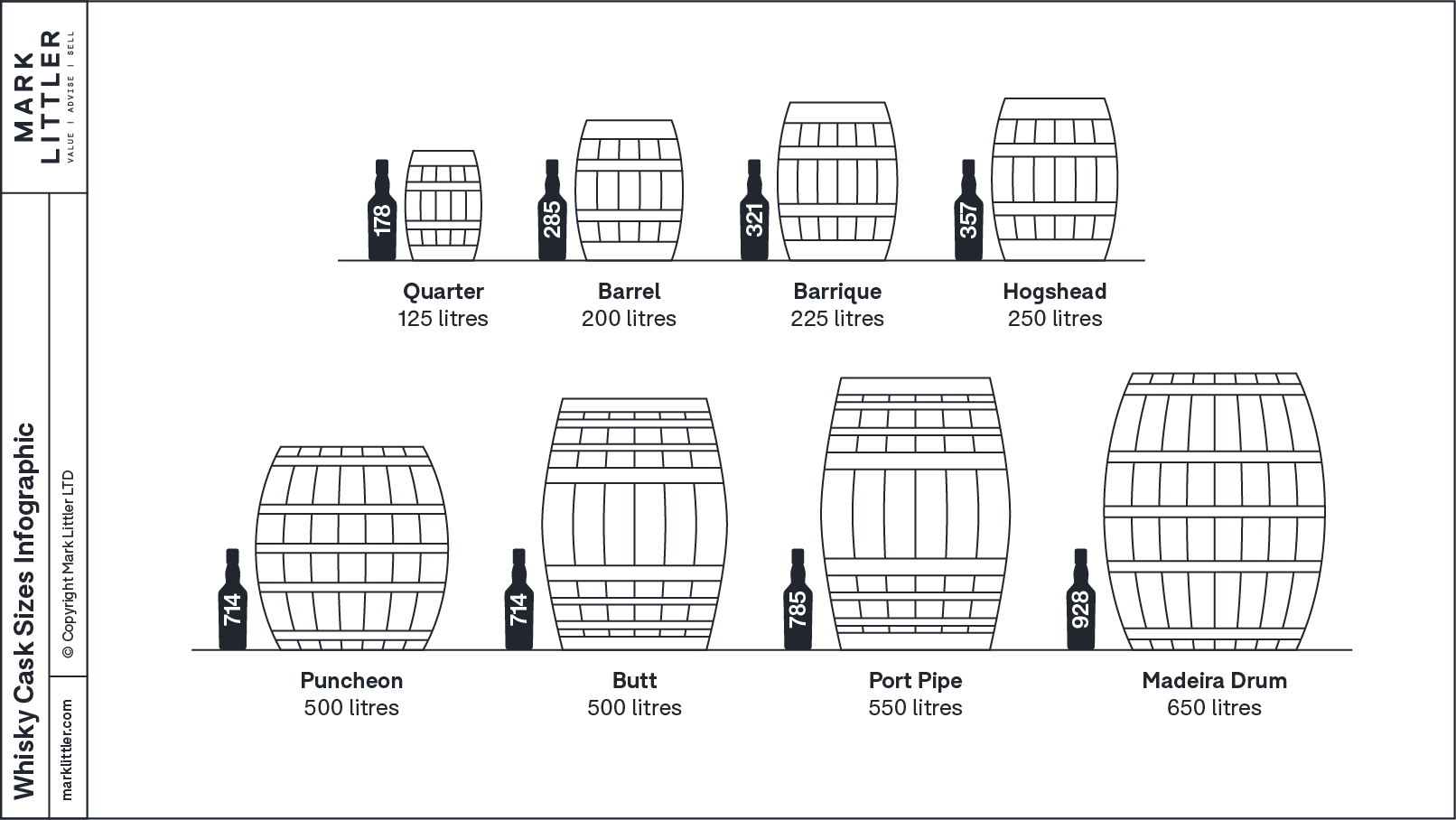

Scottish distilleries alone have the capacity to make over 400 million litres of pure alcohol each year. At an average fill percentage of 63% that is over 2.5million hogsheads every year.

The costs associated with shipping casks to bottling facilities once they had matured drove up prices – especially from remote distilleries like those on Islay. Not to mention the fact that many of the distilleries are in stunning settings in rural Scotland; locals and the booming whisky tourism business might not appreciate huge warehouses marring the story book setting of many of the most famous distilleries.

Many modern distilleries, especially those owned by the big names such as Diageo, make the spirit on site and then ship it in tankers to centralised warehouses in Scotland where it is decanted into casks and stored until it is ready to be bottled. This reduces costs hugely by vesting improving cask management and reducing transport and bottling costs (which are often nearby too).

Diageo maintain that because Scotland has a generally maritime climate that there is no discernible difference between maturing the whisky on site at the distillery and in these centralised warehouses. They say that the local climate around the distillery would not impart any influence on the cask and so the end product is the same but at a reduced cost for them, and drinkers.

Variations in local climate

Scotland does have a maritime climate, but actually so does the whole of the UK. Suggesting the climate in the Outer Hebrides is the same as Edinburgh, never mind Norfolk or Cornwall is a vast simplification.

The fact is that the geology of Scotland produces microclimates, with relatively wetter, colder, drier and warmer areas that will all impact the humidity and temperature within the warehouse. Which as we discussed earlier, impacts what proportion of alcohol to water the angel’s take.

In fact, purests suggest that even the local micro-fauna (that is the fungi and mould to be found in the distillery’s locality) would shape the way the whisky matures and impart flavours to the whisky.

The argument perhaps is how much difference does it make to the average drinker’s palate.

What’s in a name?

Outside of the pure taste considerations, one of the loudest discussions we have encountered about this in recent times revolves around the issue of provenance. How much of something has to be produced in a place, or for how long is should be there, in order to be named after that place?

Which becomes important when you consider how popular certain whisky regions are; Speyside and Islay being the two standout examples. Distilleries like Bruichladdich have argued that just distilling the spirit on Islay should not be enough; the whisky should be matured there too in order to benefit from the marketing of the Islay name.

However, visitors to Islay might not appreciate their view of the bay being marred by the vast warehouses that would be necessary to store tens of millions of litres of whisky produced in Islay each year.

Perhaps then question becomes one of balance. Taste versus cost; authenticity versus practicality. Diageo’s solution is expertly blending casks matured in different locations within their warehouses to create a comparable effect. Bruichladdich’s is keeping batches small and the increased costs associated with that choice.

Send me my free cask buying guide

How does the speed of maturation effect whisky?

The rule of thumb is that the longer a whisky takes to mature, the better. But why?

Longer maturation favours bigger casks like butts and puncheons that command a premium, high humidity dunnage warehouses that are small and inefficient to manage (or super modern air conditioned warehouses that are expensive to run) plus long periods of storage for extended maturation. So, is it that whisky that takes longer to mature is better or just that whisky that takes longer to mature is more expensive because it necessitates bigger overheads?

By contrast whisky matures faster in smaller casks and in low humidity modern warehouses that are cheap to manage. Because they mature faster the storage costs are lower. This is why barrels and even quarter casks are popular in the professional whisky industry; they get the whisky from potential to profit faster and cheaper.

Arguably, the time for maturation means the time to reach the optimum drinking point. A smaller cask means a bigger surface area to volume ration for which additive and subtractive actions happen. A warm, low humidity environment promotes reactions to happen faster. This is basic chemistry. All your doing by taking longer, is upping your costs and making the whisky more expensive. Which gives the impression that slower is better.

Whether it is based on economics or taste you cannot argue that older, bigger casks are more valuable in the current market. So, if you are looking at buying a cask as an investment looking at slow maturation and keeping your cask for a long time is a good way to think about getting the best from your investment.

Get in contact with your questions

We hope you’ve enjoyed the discussion about warehouses. But if you have any questions about buying, owning or selling a cask of whisky then please get in touch. No question is too small.